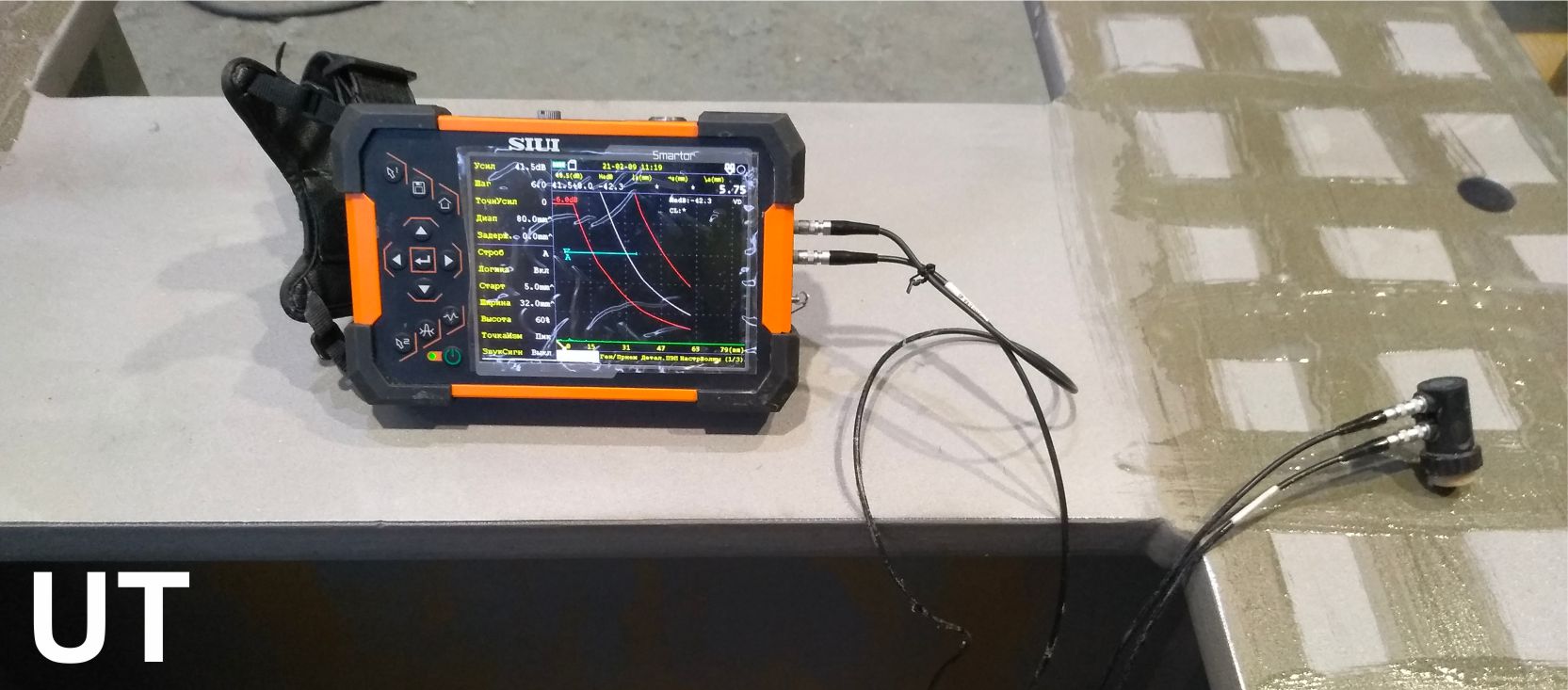

Ultrasonic flaw detection

Ultrasonic flaw detection

One of the most common types of nondestructive testing is ultrasonic flaw detection. This is an inexpensive and effective way to check the quality of welds and base metal, engineering products, which allows you to detect certain material imperfections.

Ultrasonic testing detects defects such as:

- cracks around the seam;

- shells, delaminations;

- gas pores;

- areas damaged by oxides and corrosion;

- slag inclusions;

- undercuts, burns, overlaps;

- inclusions of foreign bodies;

- non-fusion, etc.

Due to numerous advantages ultrasonic flaw detection is successfully applied in gas, oil, chemical industry, at construction sites and during construction of various buildings. Using this method greatly helps to prevent the likelihood of emergencies or reduce losses from them.

Ultrasonic flaw detection is used as for primary control of welded joints, steel structures, base metal of engineering products, when preparing the components for welding and assembling, and for diagnostics after welding works.

According to the results of the control you will get a report describing the detected defects. To order work please fill in the feedback form and our representative will contact you.

Order ultrasonic test

Projekt „Metalli kvaliteedi kontrol ja diagnostika".

Projekti eesmärk oli põhivara soetamine ja innovaatilise teenuse pakkumine.

Toetuse summa on 15 000 eurot